Engraved Plaques - The Definitive Buying Guide

A foreword from the Writer

I'm so glad Hawtons got in touch with me to write about their plaques. The study of metalworking, engraving and plaque creation is something that is steeped in heritage and represents cultures from across the ages.

Professional hand engraver personalizing fragrance/spirit/wine bottles in studio or on site events.

The origins of Engraved Plaques

Engraving, a time-honored form of human expression, has a rich and multifaceted history dating back to ancient times. One of its primary functions was to honor deities and rulers, a tradition that can be traced back to the earliest known examples of human art discovered in the Serengeti Plains of Africa, where stone carvings estimated to be around 500,000 years old have been unearthed.

The art of engraving was also utilized as a means of indicating wealth. Sumerian and Hittite carvers began crafting cylindrical ornaments made of precious materials like soapstone and lapis lazuli around 3000 BC, and these objects were often adorned with intricate designs and cuneiform writings. These seals were highly prized by the wealthy and are regarded as some of the earliest examples of engraved art.

Personalised Plaques, with a far deeper meaning

Throughout history, plaques have been utilized to commemorate achievements and honor the past. They are an enduring reminder of victories, accomplishments, and tributes. Plaques are employed worldwide to celebrate the most significant events in history, from national milestones to natural landmarks, entertainment hotspots, and memorial sites, serving as public reminders for all to see.

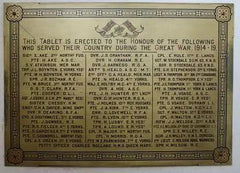

In this figure, you’ll find the War Memorial Plaque, dedicated to the soldiers who lost their lives during World War 1.

A War Memorial Plaque, in St James's Church, Holderness, UK

Excited? I am! Let me tell you about the materials that you can use to create your own piece of history.

Material choice is something that’s based on a number of factors, from durability to personal aesthetics choice. Let’s delve into the world of metal science, and let me help you decide on what material is perfect for your plaque.

Brass, a classic personalised plaque material.

When you think of an engraved plaque, what’s the first material that comes to mind? For most people, it’s brass. This wonderful material has been used for centuries to create long-lasting, beautiful plaques for a range of uses.

Let me explain the more technical details of this wonderous material.

Brass as an engraved plaque material

Brass, a metallic amalgam comprising copper and zinc in varying proportions, has been utilized since antiquity owing to its distinctive attributes. From coins and jewelry to industrial applications like shipbuilding, this alloy’s versatility has earned it a place of honor. In this article, we shall delve into the reasons behind brass’s popularity, its usage, and the advantages it offers.

What Makes Brass So Popular?

Brass has been a favorite for centuries due to its resilience and resistance to corrosion. Its pliability makes it easy to mold into various shapes and sizes, making it ideal for use in intricate jewelry or large-scale construction projects. It is a staple in musical instruments, door knobs, keys, locks, and hinges, as well as outdoor fixtures such as bollards and posts.

And the specific advantages of Brass? Personalised plaques are ideal for this material.

Advantages of Brass: The benefits of employing brass are manifold. First and foremost, it is a sturdy material, rendering it suitable for use in construction projects where durability is essential.

Its high copper content – over 60% – ensures it has excellent resistance to corrosion. This implies that brass components will outlast those manufactured from other metals, such as aluminum or steel.

Additionally, brass boasts superb electrical conductivity, making it suitable for wiring systems or electrical components like switches and sockets. Finally, brass is non-magnetic, rendering it perfect for use in sensitive equipment such as medical scanners or navigation systems.

Why plaques are made from Copper, the natural Super-Metal.

Copper is an incredibly resilient metal, with a history dating back more than 8,700BC

This metal does not contain any iron, otherwise known as “non-ferrous”. This gives it the enormous advantage of not being able to rust. Copper does oxidise, but can withstand high levels of natural wear, and it’s not uncommon for copper items to laser hundreds, if not thousands of years.

316 Stainless Steel as a personalised plaque material

316 Stainless Steel, otherwise known as “Marine Stainless Steel” is a highly corrosion-resistance steel alloy, which ranks as one of the highest grades on steel in the world.

Stainless steel 316, an alloy composed of 16 to 18% chromium, 10 to 14% nickel, 2 to 3% molybdenum, and a small percentage of carbon, is renowned for its exceptional properties. The addition of molybdenum provides remarkable corrosion resistance, surpassing that of other stainless steel grades. Furthermore, incorporating other alloys can significantly enhance its properties.

This remarkable alloy, stainless steel 316, is the second most widely used stainless steel grade after stainless steel 304. Its properties make it particularly useful in harsh environments, such as chemical plants, refineries, and marine equipment.

Stainless steel 316 has several variants, with each designed to cater to specific applications. For instance, stainless steel 316L has a lower carbon content, and it is used in situations that expose the metal to sensitization risks. Conversely, stainless steel 316H, with its higher carbon content, offers greater thermal stability and creep resistance. Additionally, the stabilized 316Ti is widely used and offers better resistance to intergranular corrosion.

How long will my plaque last?

Our plaques are designed to stand the test of time. Using a combination of high-quality materials, and industry-leading laser technology, we expect our plaques to last until the next century with proper care.

What about cleaning and maintenance of my engraving?

While metal letters and standard finished plaques, with the exception of anodized and stainless steel, are coated with clear poly paint to protect them from corrosion, periodic cleaning may still be required based on their location. It is recommended to clean these letters with warm, soapy water and a soft cloth, as harsh cleaners with chemicals can damage the clear poly coating. This should be done every few months or as needed to maintain the original finish.

Stainless steel, on the other hand, is designed to stain or corrode less than other metals due to a thin layer of chromium oxide that forms a passive film and protects the steel from further corrosion. However, contamination from dirt or exposure to salty air and chemicals can hinder the passivation process and trap corrosive agents. Thus, routine cleaning is necessary to protect not only the appearance of the letters, but also the integrity of the metal.

Scratches in letters can be a distraction, especially in interior installations. Smaller scratches can be minimized by washing the letter and applying car wax, then buffing the scratch with a soft cloth. Deeper scratches can be removed by wet sanding with extra fine-grit sandpaper and applying a liquid paste such as Finesse-it. If deep scratches cannot be buffed out, they will have to be sanded with 1200 grit paper and repainted. It is important to maintain the integrity of these materials to ensure their longevity and continued effectiveness.

No comments